Experience

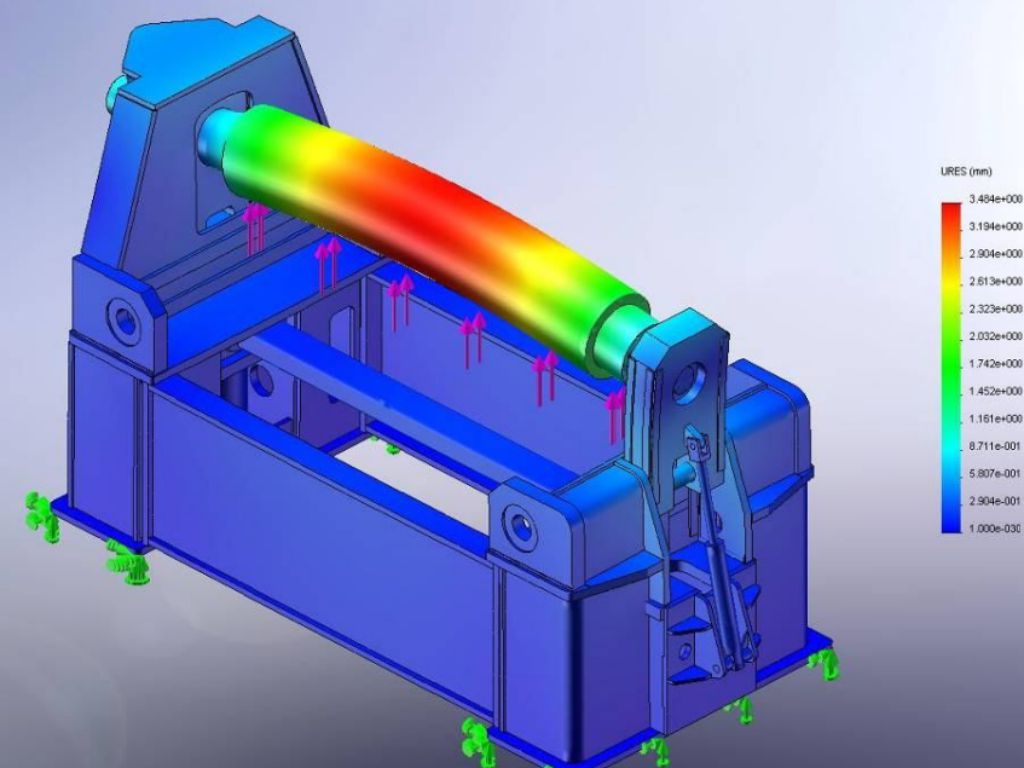

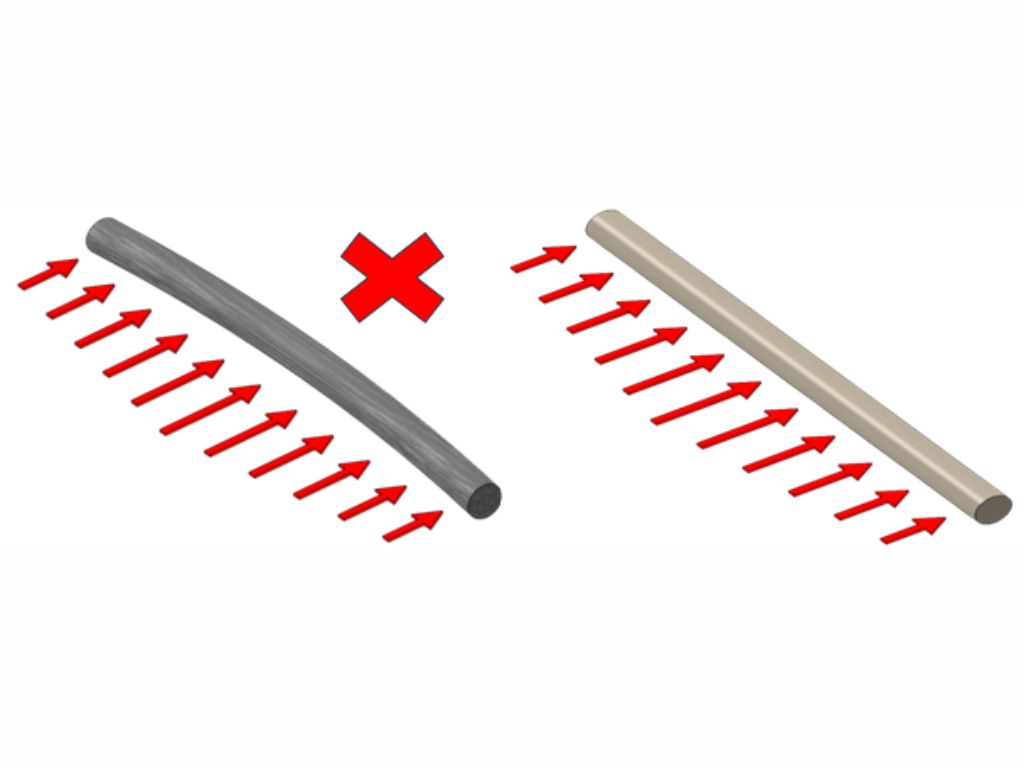

Seamless & Precise Bending with Our 3-Roll

Plate Rolling Machine

Download our brochure or request more information to learn about how Monotech can help you achieve your manufacturing goals.