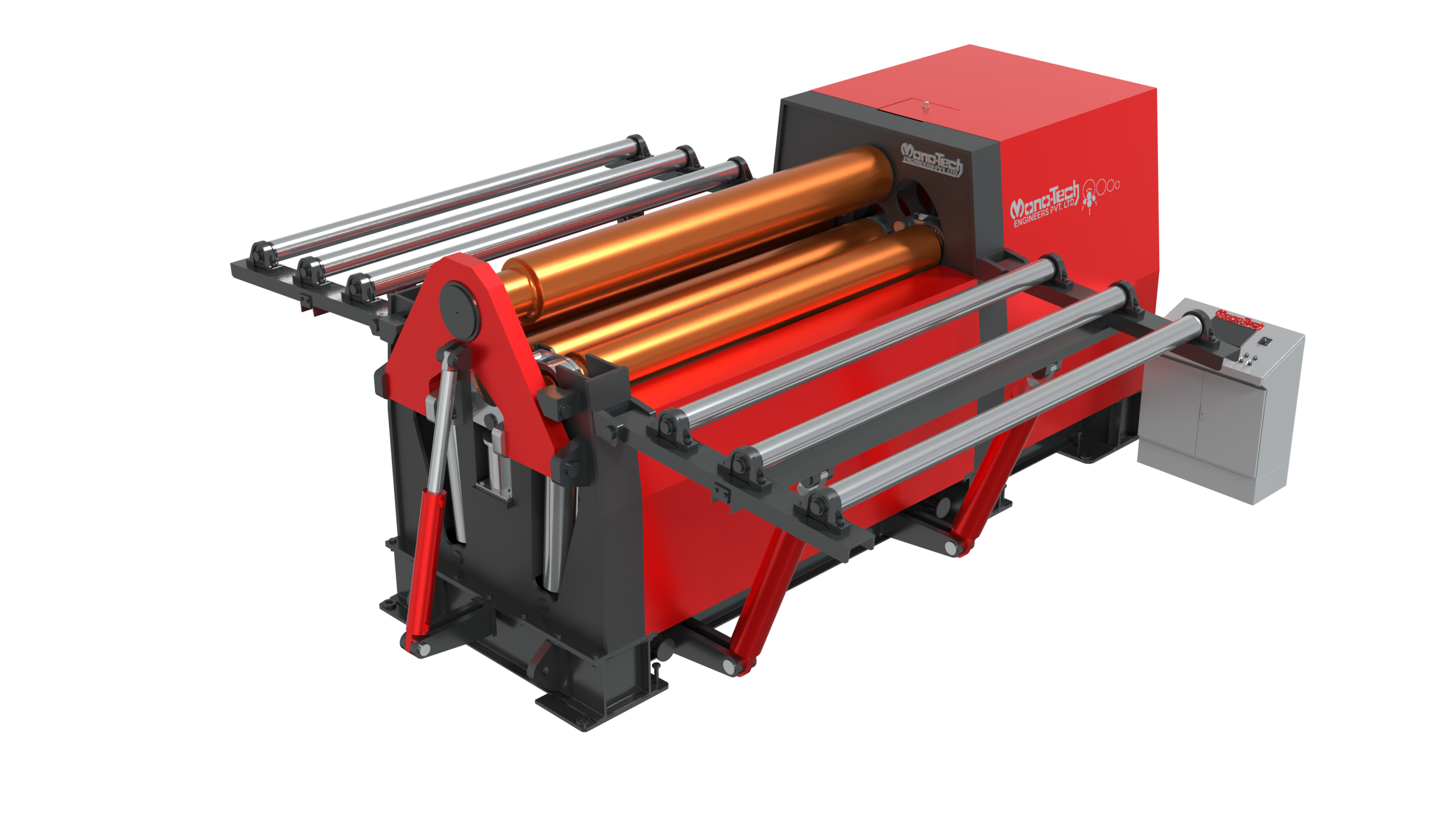

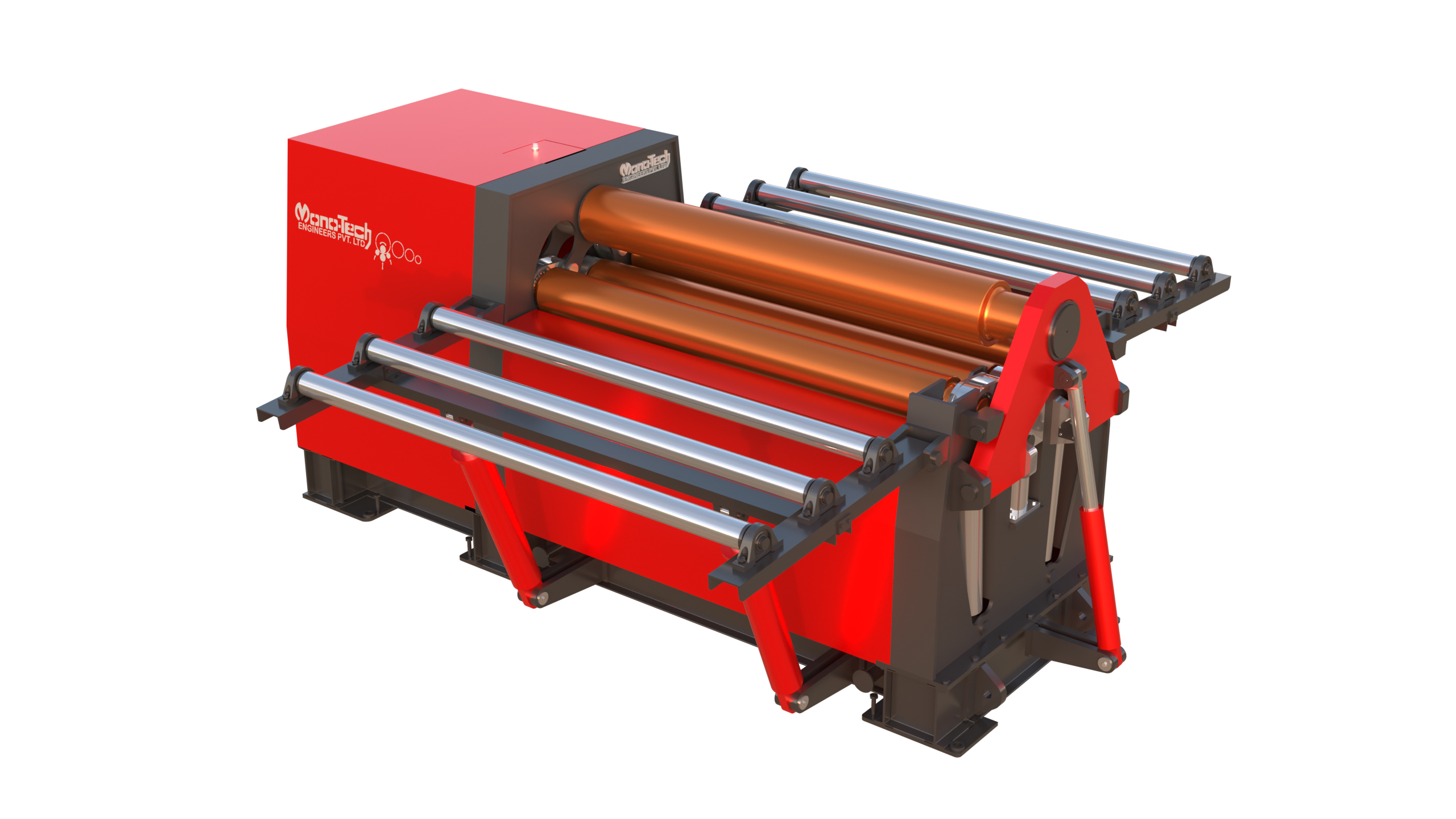

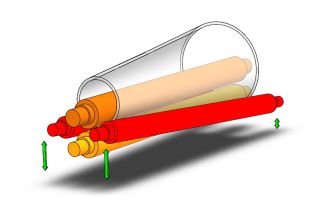

Machine

Effortless Precision in Plate Rolling

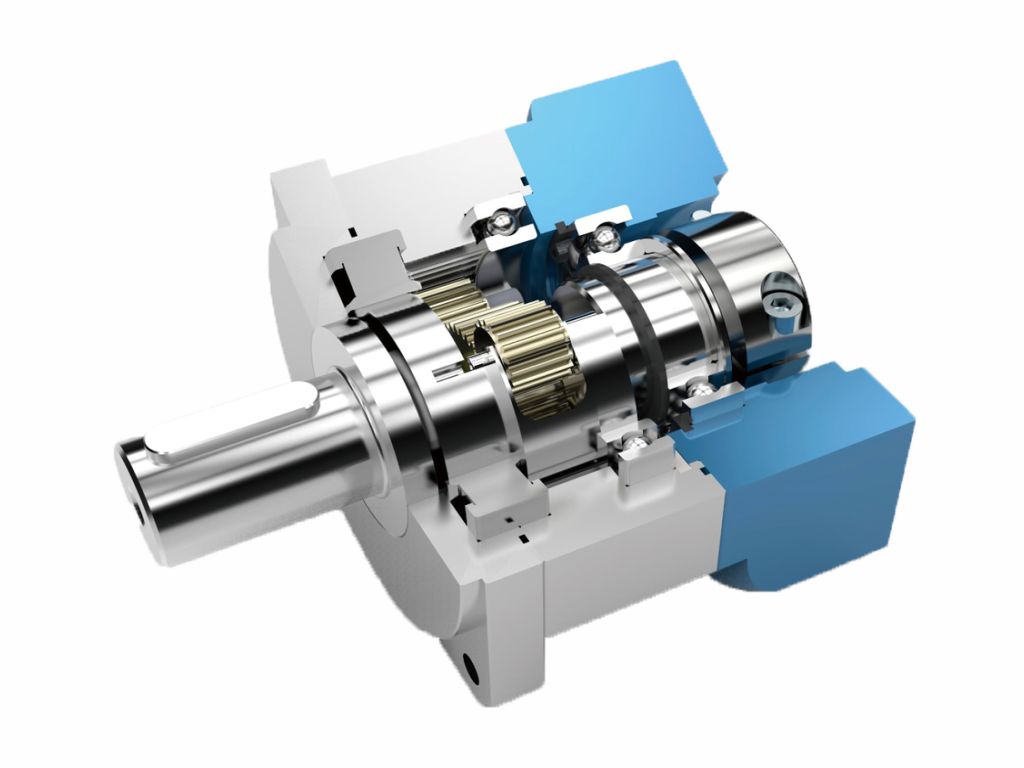

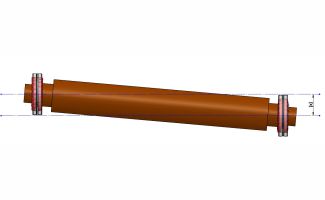

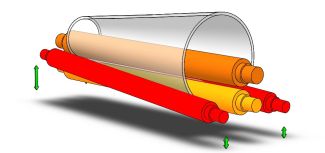

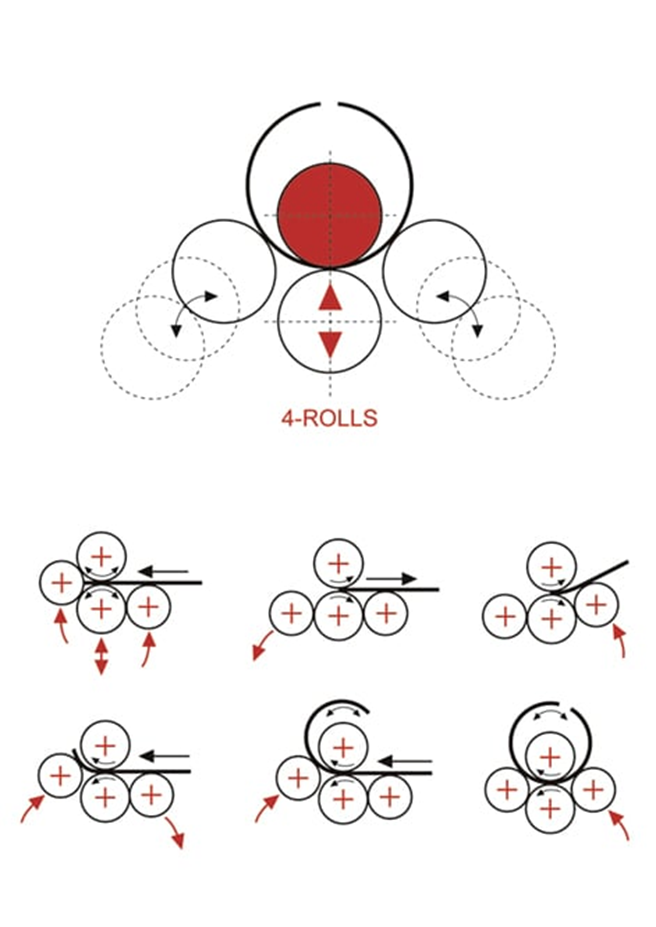

At Monotech Engineers Pvt Ltd, our advanced Four Roll Plate Bending/Rolling Machines are engineered for seamless operation, energy efficiency, and superior performance. Designed to handle heavy-duty plate rolling tasks with ease, our machines enhance productivity while minimizing operational efforts

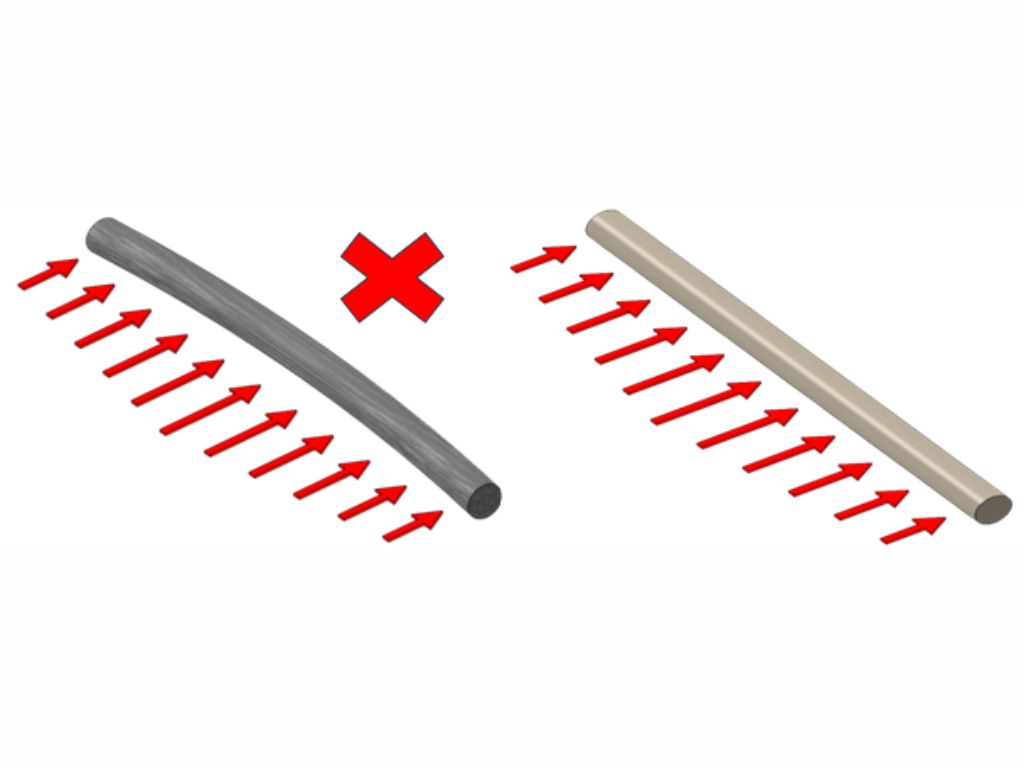

Our cutting-edge linear-guided systems bring multiple advantages to your fabrication setup—exceptional precision, long-lasting durability, reduced capital investment, and lower maintenance costs—giving your business a competitive edge.