Four Roll Plate Bending/Rolling Machine

Unmatched capacity. Superlative precision. Optimal turnout.

Unmatched capacity. Superlative precision. Optimal turnout.

Our top-of-the-line Four Plate Roll Bending/Rolling Machines are designed for hassle-free usage and energy-saving features to ensure peace of mind and operational ease for heavy plate rolling jobs.

Monotech linear guided machines deliver a multi-fold advantage to your fabrication infrastructure - a remarkably efficient and lasting performance, an unbeatable edge bending precision, reduced capital expenditure, and lower ongoing operational and maintenance costs.

Roll Movement in Four Roll Design

A major factor is position accuracy in the press brake. You want an accurate machine to make the best bends possible with your materials. When you buy a Monotech press brake instead of an conventional one you can guarantee the position accuracy is dialed in. Enjoy saving money and time with an accurate press brake.

You’ve heard the phrase, “time is money.” Your new Monotech press brake will perform better than conventional one, hands down. Our machine is more accurate, more efficient, and built (typically) on newer technology. Get a Monotech press brake to take advantage of increase performance and take 10% off your cycle times.

Monotech press brakes tend to be more energy efficient than Conventional ones. They’re built on better technology and require less pull to operate. This means you’re spending less on utilities to run the machine, which means you can reinvest those Rupees to get another press brake or even tighten up other areas of your production line.

Reduced noise improves your work environment, as well as allows for clear communication to occur. Get rid of noise issues and get a Monotech press brake.

The biggest benefit to Monotech press brake machines is the cost-effectiveness of their operation. Our machines lasts longer and are much more durable than a conventional Press Brake. Our machines require less maintenance & negligible breakdown calls, thereby making it much more cost effective by offering you hassle free smooth operations!

| Model | Width (Span) | Top roll size | Bottom roll size | Side Roll Size | Rolling | Pre-pinching | ||

|---|---|---|---|---|---|---|---|---|

| 2.5BR | 5BR | 2 T | 3 T | |||||

| Fully Hydraulic Plate Bending Machines | 2.5BR | 5BR | 2 T | 3 T | ||||

| FDC/25 | 2500 | 250 | 250 | 215 | 12 | 14 | 7 | 08 |

| FEC/25 | 2500 | 280 | 280 | 245 | 15 | 18 | 9 | 12 |

| FGH/25 | 2500 | 330 | 330 | 270 | 18 | 23 | 12 | 15 |

| FHH/25 | 2500 | 360 | 350 | 290 | 23 | 28 | 15 | 19 |

| FJH/25 | 2500 | 400 | 390 | 320 | 28 | 37 | 19 | 23 |

| FKH/25 | 2500 | 450 | 440 | 370 | 37 | 46 | 23 | 28 |

| FLH/25 | 2500 | 490 | 480 | 400 | 43 | 52 | 28 | 37 |

| FMH/25 | 2500 | 540 | 520 | 440 | 50 | 58 | 37 | 43 |

Ever since the inception, Monotech Engineers Pvt. Ltd. have put the best foot forward and created the best industrial machinery/equipment according to the client’s demands. Being an ISO 9001:2015 certified company, we believe in making just and fair deals with our clients. For that we have the best team one could ask for. With the support of an experienced and dedicated team of professionals, we have been able to serve reputable government and private agencies such as BHEL, BEML, Defense Unit, and NTPC.

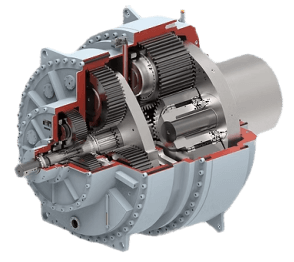

The rolls are the most important elements of our machines. Monotech designs the rolls with optimal diameter and uses forged carbon steel rolls that are machined by high precision CNC lathes. Our rolls have a special spline-based design that is extremely efficient in connecting the rolls with the planetary gear system. This diminishes points of roll failure compared to welded connections provided by other manufacturers.

Additional energy saving is ensured in our Four Roll machines by a hydraulic system which can work at less than full capacity when jobs less than maximum thickness are rolled.

Monotech Engineers Pvt. Ltd used in our machines is efficient and eliminates energy wastage associated with heavy-transmission systems and yet achieves the goal of speed reduction by increasing the stages in gears and pinions.

Edge bending can be done before or after shell rolling depending on operator skill and choice. Thin plates can be rolled and edge-bent in a single pass.

The cone bending process with the K series is simple. The bottom rolls need to be inclined to achieve cone bending geometry. This is controlled and monitored by electronic microprocessor (on some models).

Our control system also ensures easy and accurate return to parallel setting after cone bending resulting into precision on repetitive jobs.

Our state-of-the-art technology in forming cylinders

and cones delivers unmatched precision

and efficiency.

Designed for ease of installation,

these systems are extremely user-friendly and convenient

to service, ensuring minimal

downtime. With a straightforward interface

Other than cylinders and cones, other non-circular shapes like oil tankers and elliptical shells can be made using a PLC version.

Due to the exceptional build quality, failure-resistant linear guideway design, high operational precision and a wide range of jobs that can accurately rolled, the F series machines prove to be the most attractive investment for any type of industry, regular production or a job shop.

Alongside our excellent design and build quality, we provide the following additional features and accessories upon request from our client.

Induction Hardened Rolls having Surface Hardness between 42 to 55 HRC for additional durability and longevity.

Including central and side shell support, tilting conveyors, hardened rolls and PLC/CNC capabilities

Central & side shell supports provide ease of operation, operational cost saving and productivity while increasing safety of workers.

Hard chrome plated rolls for special applications in Pharma and Dairy Industry.

Tilting tables for support while feeding plates at specific angles. Specially useful for plates of larger lengths.

Powered Conveyors that provide ease of plate feeding in case of longer plate lengths, improved machine performance and longevity.

PLC Controllers provide precision, ease of operation, while identifying needs for preventive maintenance to increase machine life and optimize productivity.

We are in the process of developing CNC system for the Four Roll Machine.

A major factor is position accuracy in the press brake. You want an accurate machine to make the best bends possible with your materials. When you buy a Monotech press brake instead of an conventional one you can guarantee the position accuracy is dialed in. Enjoy saving money and time with an accurate press brake.

You’ve heard the phrase, “time is money.” Your new Monotech press brake will perform better than conventional one, hands down. Our machine is more accurate, more efficient, and built (typically) on newer technology. Get a Monotech press brake to take advantage of increase performance and take 10% off your cycle times.

Monotech press brakes tend to be more energy efficient than Conventional ones. They’re built on better technology and require less pull to operate. This means you’re spending less on utilities to run the machine, which means you can reinvest those Rupees to get another press brake or even tighten up other areas of your production line.

Reduced noise improves your work environment, as well as allows for clear communication to occur. Get rid of noise issues and get a Monotech press brake.

The biggest benefit to Monotech press brake machines is the cost-effectiveness of their operation. Our machines lasts longer and are much more durable than a conventional Press Brake. Our machines require less maintenance & negligible breakdown calls, thereby making it much more cost effective by offering you hassle free smooth operations!

Globally administrate bleeding-edge content via viral solution. Phosfluo rescently grow progressive schemas and front-end portal. Conveniently. Authoritatively envisioneer strategic technology with optimal synergy. Professionally productize magnetic metrics.