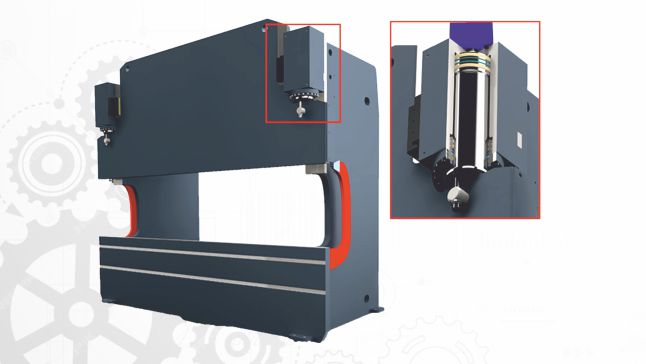

Semi CNC Hydraulic Press Brake

Accuracy of CNC. Affordability of NC. Innovation by Monotech

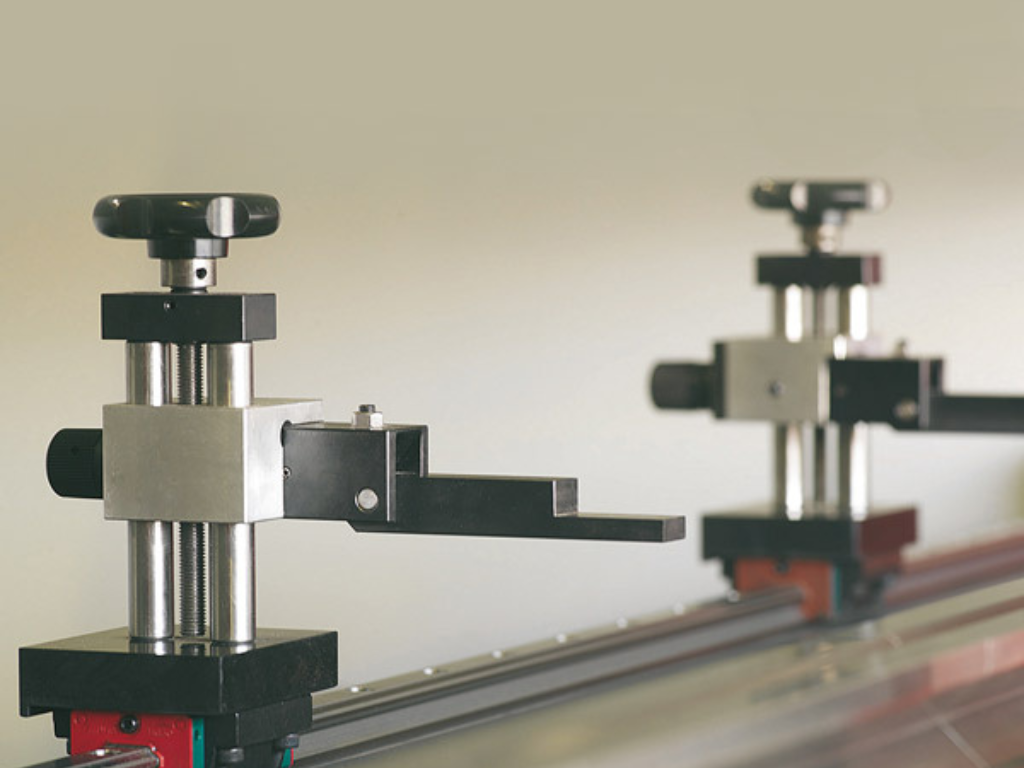

At Monotech Engineers Pvt Ltd, we’ve bridged the gap between conventional and CNC technology with our revolutionary Semi CNC Hydraulic Press Brake. Unlike standard models, our proprietary design delivers true independent control of Y1 and Y2 hydraulic cylinders — electrically, without any mechanical restriction. This groundbreaking system, developed entirely in-house, provides CNC-level precision and extended machine life at 60–70% less cost than a full CNC press brake.